More than ever, contractors, fleet managers, and auto shops are seeking companies that specialize in using polyurea spray coating equipment to line truck beds and van interiors as a way to protect from them wear and tear. If you are in construction or trades, you know just how quickly tools and machinery can damage truck beds and interior surfaces. Between hauling tools, materials, and heavy equipment, traditional paint or liners don’t hold up. You need a tough, abrasion resistant material like polyurea, which is the gold standard for permanent spray-on protective coating.

Polyurea spray coating is a fast-set, ultra-durable coating that offers a seamless protective barrier against:

- Abrasion and impact damage

- Water, oil, and chemical exposure

- UV degradation

- Rust and corrosion

Unlike drop-in liners or roll-on coatings, polyurea is sprayed on to form a permanent bond that won’t crack, peel, or shift over time. It’s also quick to apply, cures in seconds, and is fully cured in 24 hours, minimizing downtime and getting vehicles back in service fast.

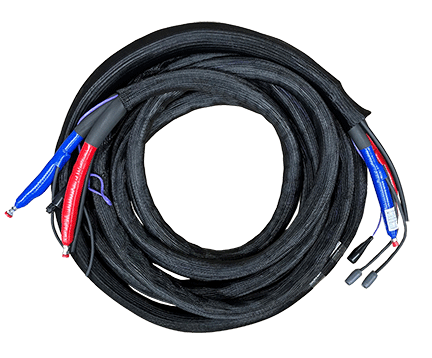

The Right Polyurea Spray Coating Equipment: PMC Xtreme Spray Gun + PHX-2 High-Pressure Proportioner

While the coating material is essential, the equipment behind the application is what makes or breaks a successful job.

PMC Xtreme Spray Gun: Built for Precision and Power

The PMC Xtreme Spray Gun for high-output, high-performance polyurea jobs offers:

- Lightweight, ergonomic design that reduces fatigue during long spray sessions

- Quick teardown and reassembly for easy maintenance and cleaning

- Powerful atomization to deliver an even, consistent finish with minimal overspray

This gun is designed with applicators in mind, so you get quality results without fighting your equipment.

PHX-2 High-Pressure Proportioner: Consistency You Can Count On

To get polyurea’s fast-setting formula just right, you need polyurea spray coating equipment that delivers optimal heat, high pressure, and precision. The properties of polyurea require that is is applied under high pressure so that sprays at the proper atomization and cures to a hard shell. The PHX-2 is one of PMC’s high-pressure plural-component proportioners made for demanding protective polyurea spray coating applications.

Key benefits of PMC Polyurea Spray Coating Equipment include:

- Precision ratio control for optimal mixing of polyurea components

- Adjustable temperature and pressure settings to handle a range of coatings

- User-friendly controls and robust operation

- Rugged build quality for reliability on the jobsite or in the shop

RECOMMENDED POLYUREA SPRAY COATING EQUIPMENT

Together, the Xtreme Gun and PHX-2 ensure fast, flawless applications with less waste and rework. Alternate machines are the PKX-25, PHX-25, PHX-40, PHX-55, and the new Premier X, coming soon.

Versatility That Goes Beyond Vehicles

While truck beds and van interiors are popular use cases, the same polyurea spray coating equipment will work for:

- Utility trailers

- Service Vehicles

- Agricultural equipment

- Marine decks

- Flooring or containment areas

When protection matters and time is money, PMC’s polyurea spray coating equipment gives you the edge.

Ready to Get Started

Find the right PMC distributor in your area and equip your operation with the best tools for protective spray coating machinery, or contact us today.